Manually operated presses Manually operated presses

The first pad-printing presses were manually operated (Figure 1). Very high quality watch and instrument dials have been printed over the years using hand powered machines. Now, the only reason for buying them is the low initial cost. Except in cases where pad printing will be carried out on a small scale, they are not really entry-level machines. Print rates are very low, and maintaining quality over a continuous run is extremely difficult. A well-engineered unit can be useful for testing cliches, pads, inks, and designs as an alternative to taking a production machine off line.

Open ink trough Open ink trough

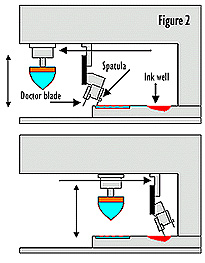

Many machines of this type (Figure 2) are out in the field. This was the original semiautomatic system, dating to the late 1960s/early 1970s, and has been the basis of many clones. The original machines were mechanically operated, giving little opportunity for adjusting individual press functions because the inking mechanism and pad stroke were tied together on the same drive. Printing speed was controlled by adjusting the speed of the main drive motor. Later, more sophisticated mechanically driven machines gave greater flexibility of adjustment. This is a very robust system with a smooth printing action that is unaffected by fluctuations in air-line pressure.

Over the years, this style has been further developed, and a host of machines have been produce using electropneumatics and even servo-motor drives. Also, PLCs (programmable logic controllers) are common, providing a wide range of sequencing options.

Partially covered ink troughs Partially covered ink troughs

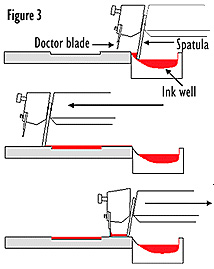

In this style, ink is contained in an ink trough located behind the cliche, as shown in Figure 3. The ink is pulled forward out of the trough by a spatula that is mounted on a horizontal carriage together with the doctor blade assembly. While ink is being flooded across the cliche, the horizontal carriage covers it and reduces the solvent evaporation. When retracted, the mechanism covers the ink trough. Let me make it clear that this does not seal in the ink as with a closed-cup press, but it does inhibit the evaporation of solvents. The ink/solvent mix will remain stable longer than in a completely open trough.

Sealed ink cups Sealed ink cups

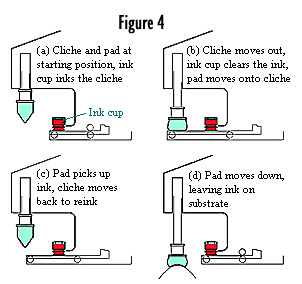

The concept of these presses is to contain the ink in a cup that is turned upside down. The cup is pressed firmly against the cliche, sealing in the ink. The cup not only holds the ink but acts as a doctor blade as well; it traverses back and forth across the cliche, leaving ink only in the etched areas. The obvious advantage of this system is that solvent evaporation is reduced to a minimum. This allows much closer control of ink conditions, resulting in the opportunity for reduced downtime and partially unmanned operation. One thing to notice is that the cost of an ink cup range from a few hundred to more than a thousand HK dollars. Fortunately, if the damage to the cup is very slight, it can be repaired by carefully honing the contact surface on a fine carborundum stone. Some cups can be remachined at a quarter of the replacement costs. This all means that the cups must be handled very carefully.

There is no doubt that the sealed-cup systems are being further refined. They were available only in limited print sizes originally, but the use of larger cups is changing this. Another interesting variation on the closed-cup press involves the use of cliches that are mounted inside the ink container vertically rather than horizontally. The cliche rises straight up out of the container, with a doctor blade at the top scraping ink from non-image areas as well as sealing ink in the container from solvent evaporation. The pad moves horizontally to pick up the image from the cliche and, depending on the application and the press design, rotates either 90�X or 180�X to deposit the image on the substrate. The ink/solvent mixture is nearly as stable as in a closed-cup system, but larger areas can be printed as large as 5 x 18 in. (12.7 x 45.7cm).

One additional benefit of sealed inking systems: They reduce the level of solvents that are exposed in the working environment and expelled into the atmosphere.

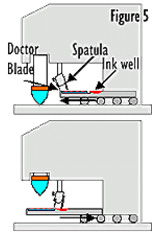

Reciprocating cliches Reciprocating cliches

In these models, instead of the pad moving back and forth from cliche to substrate, the cliche moves out of the way, while the pad remains stationary. This type of machine results in less vibration of the pad and faster machine cycling. The single-plane pad movement in this press provides a cost saving for the machine manufacturer because there is one less actuation on the machine. These reciprocating cliches (Figure 5) work much like reciprocating-table in screen-printing presses. This press design is available with either closed cups or open ink troughs.

One application for this system is high-speed coding machines, which some manufacturers claim, run at up to 10,000 cycles/hr. Larger machines with cliche areas of 8 x 18 in. (20.3 x 45.7 cm) have been produced using this method, but they need very substantial bearings to support the cliche in the pickup position because the loading pressure exerted by a large pad is considerable. Depending on the press, the ink trough may be shrouded at rest or for half the cycle during operation, helping to maintain the solvent balance.

Manufacturers claim that since the pad strokes below the base of the machine, it has a larger work area. The downside to this is that the machine must be well guarded because the forward movement of the cliche can potentially be a severe trapping hazard.

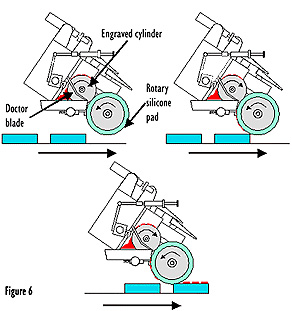

Rotary presses Rotary presses

Rotary pad-printing systems (Figure 6) developed directly from gravure printing. They are very suitable for cylindrical parts and continuous flat printing.

These presses use a rotary drum type silicone pad in conjunction with a steel cylinder cliche. The design is etched into the cylindrical cliche, and the ink flows onto it from an ink trough or ducts. A doctor blade removes the excess ink. As the cylinder rotates, the silicone-rubber printing roller picks the ink out of the etching and transfers it onto the substrate.

One advantage of this system is its speed. With small components such as bottle caps and container closures, 120,000 parts/hr can be achieved. Another advantage is the very fine detail that can be printed with rotary presses.

Ink deposits tend to be slightly less than in conventional pad printing, particularly at the higher speeds that are attainable. Also, the ink must be run with high levels of solvent. Each colour may require a separate solvent mix that must be determined at the start of a job and maintained throughout and on subsequent runs. Control of the solvent balance is essential.

The capital cost of rotary systems is relatively high because a feeding system is almost always necessary to make full use of the technique. Output levels keep the cost per print extremely competitive. The quality should be as good as, if not better than conventional pad printing.

There is continuous development of pad printing machines to suit manufacturers need. Other examples include TOTAL COLOUR TRANSFER SYSTEM which combines pad and screen printing technique, CAROUSEL STYLE SYSTEM which uses two rotary tables and a rotating pad carousel to print multiple colour, VERTICAL PRINTING MACHINE which can print on vertical or angled surface and machine with COMPUTER NUMERIC CONTROL which is operated by computer system. Choosing a pad printing machine is not easy, feel free to contact us for more details.

Peter Kiddell

Peter Kiddell has been in the pad printing industry for more than 20 years and currently works as a pad and screen printing consultant. His company, PDS Consulting, develops training packages to help companies fine tune their pad printing process. He or his partner, Carol Burnside, may be contacted at:

PDS Consulting, Innovation Way, Barnsley S75 1JL, South Yorkshire, England

Tel: +44(0)1226 249590 Fax: +44(0)1226 294797

Email: peter@pdsconsulting.co.uk Web: http://www.pdsconsulting.co.uk |